The 3S three-screw pumps consist of a broad range of low maintenance pumps for lubricating, non-abrasive and chemically inert liquids. 3S pumps are the best choice in many various industrial applications.

A Universal Design

The 3S Series has been thoroughly engineered and is applicable for a variety of applications. With a range of 29 different pump sizes and delivering rates ranging from 5 – 2.900 l/min @ 1450 rpm, the 3S Series is one of the most comprehensive three-screw pump ranges that is available in the market. The individual pump sizes are available in several executions, which ensures a high degree of flexibility when specifying a pump for specific system designs.

Low Maintenance

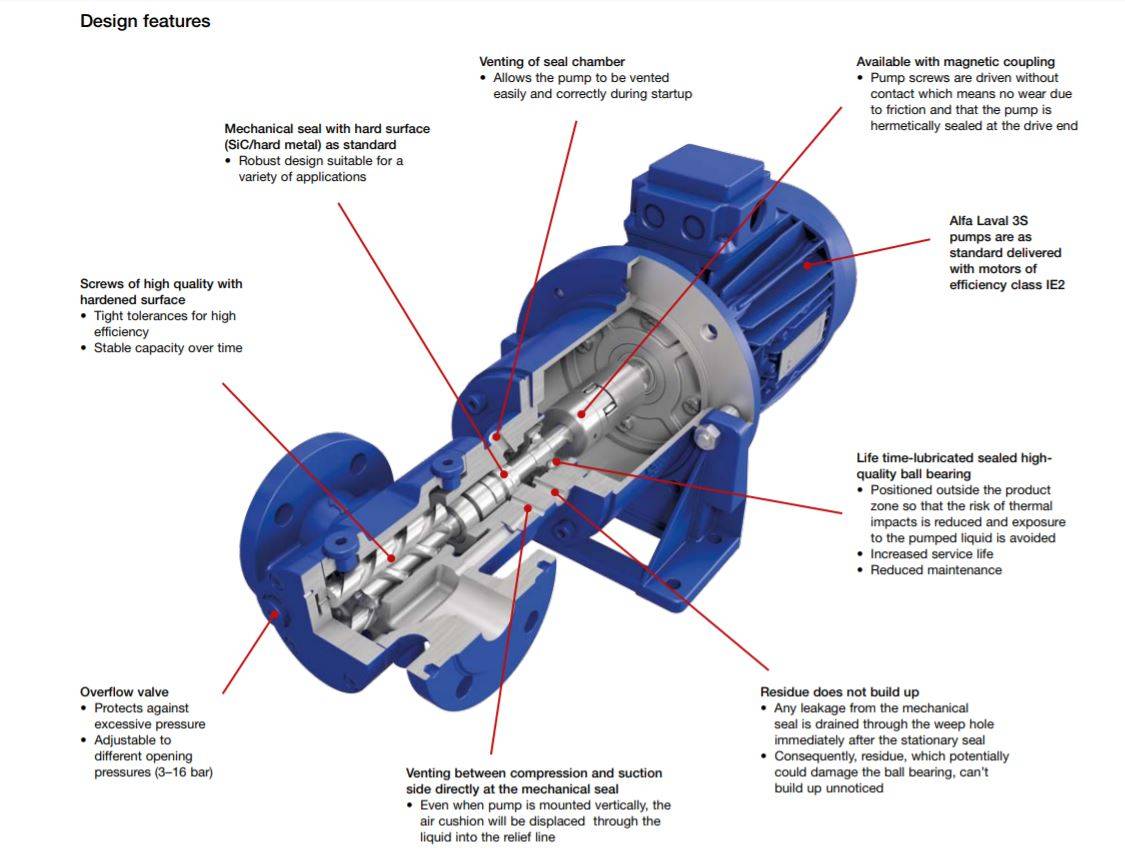

The 3S Series Pump is designed with a lifetime-lubricated external ball bearing with an expected lifetime of 30.000 hours. With a weep hole between the shaft seal and the bearing, preventing accumulation of residue the bearing becomes well protected. The ball bearing is not exposed to the pumped liquid. The mechanical seal is well lubricated and cooled. The seal is designed for efficiency in dissipating frictional heat.

Magnetic Coupled Version

The 3S Pumps are available in a magnetic coupled version. The pump is hermetically sealed and the liquid cannot escape or react by coming into contact with other materials.

*Alfa Laval’s 3S Design Features

Applications

The 3S Series consists of a broad rage of pump sizes for lubricating, non-abrasive oil based liquids. 3S Pumps are used in marine and industrial applications. The applications are used in such manner;

Benefits

The key benefits that is highlighted significantly for the 3S Pump design are;

Technical Data

| Materials | |

| Pump Casing | Nodular cast iron, EN-GJS-400 |

| Screws | Nitration-hardened steel, 1.7139 |

| Seal Faces, Mechanical Seal | SiC/Hard Metal |

Port Connections

Motors

According to IEC Metric Standard;

| Type | Power (rpm) at 50Hz | Power (rpm) at 60 Hz |

| 2 poles | 2,900 | 3,500 |

| 4 poles | 1,450 | 1,750 |

| 6 poles | 950 | 1,200 |

*IP55, insulation class ICLF, efficiency class IE2

Design

3S casings are made of nodular graphite, EN-GJS-400, and screws are of nitrated steel 1.7139. High quality mechanical seal with special SiC graphite material as standard.

3S pumps are available in several executions, e.g with free shaft end , as unit on bracket foot or vertical pedestal. Furthermore, each pump size is available inline as well as top flange design.

The basic principle of the 3S Screw Pump is that the turning screws isolate fluid and convey it. The conveyance thus takes place through the axial displacement of closed volumes.

The rise in pressure is directly related to the length of the screws.

Operating Principle

Three-screw pumps are rotary positive displacement pumps. By the meshing of three rotating screws and the enclosing pump casing, the displacement effect is created. The screws are radially supported by the sliding contact in the casing, which requires lubrication by the pumped liquid. The axial support of the main screw is carried out by a ball bearing.

The pump is equipped with an internal relief valve which will limit the differential pressure and protect the pump from excessive pressure. On the Alfa Laval 3S pump. the valve setting is adjustable to different opening pressures.

3S models

The variety of models within the Alfa Laval 3Srange enable numerous installation methods.

| 3S BI Inline flange with or without bracket foot Sizes: 0005–2900 | 3S BT Top flange with or without bracket foot Sizes: 0005–0210 | 3S VI Inline flange on vertical pedestal Sizes: 0005–2900 | 3S VT Top flange on vertical pedestal Sizes: 0005–0210 | 3S BS Special top flange with or without bracket foot Sizes: 0015–0085 |

|  |  |  |  |

© 2021 ABS Engineering & Trading Sdn. Bhd. All Rights Reserved.